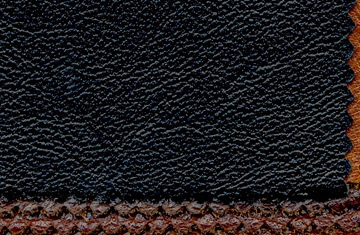

We are one of the leading Finished leather manufacturing company ,TMS Leather’s range includes Full Aniline and Semi Aniline finishes in, Sheep, Cow and Buffalo.Buffalo leather is stronger than cow and has a special grain pattern. Various leather types that are normally finished in buffalo at more competitive price level. We are capable of exporting finished leather items as per your need,without any harm, in any quantity and are capable to meet your import requirements round the year.

Full-grain leather refers to the upper section of a hide that previously contained the epidermis and hair, but were removed from the hide/skin.

Full-grain refers to hides that have not been sanded, buffed, or snuffed (as opposed to top-grain or corrected leather) in order to remove imperfections (or natural marks) on the surface of the hide. The grain remains in its natural state allowing the best fiber strength and durability. The natural grain also has natural breathability, resulting in less moisture from prolonged contact. Rather than wearing out, it will develop a natural patina over time, with some cracking and splitting. The finest leather furniture and footwear are made from full-grain leather. For these reasons, only the best raw hide is used to create full-grain leather. One way to test if leather is full-grain is to lightly scratch its surface with your nail. If it leaves a lighter-colored streak, it's full-grain.

Full-grain leathers are typically available in two finish types: aniline and

semi-aniline.

Full-grain leather refers to the upper section of a hide that previously contained the epidermis and hair, but were removed from the hide/skin. Full-grain refers to hides that have not been sanded, buffed, or snuffed (as opposed to top-grain or corrected leather) in order to remove imperfections (or natural marks) on the surface of the hide. The grain remains in its natural state allowing the best fiber strength and durability. The natural grain also has natural breathability, resulting in less moisture from prolonged contact. Rather than wearing out, it will develop a natural patina over time, with some cracking and splitting. The finest leather furniture and footwear are made from full-grain leather. For these reasons, only the best raw hide is used to create full-grain leather. One way to test if leather is full-grain is to lightly scratch its surface with your nail. If it leaves a lighter-colored streak, it's full-grain. Full-grain leathers are typically available in two finish types: aniline and semi-aniline.

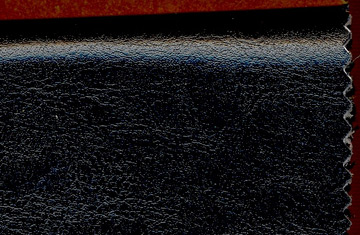

Top-grain leather is a misnomer: it gives the false impression that it is "top" quality. In fact, full-grain is the highest quality. Top-grain leather is the second-highest quality. Its surface has been sanded and refinished. As a result, it has a colder, plastic feel, less breathability, and will not develop a natural patina. However, it does have 2 advantages over full-grain leather: it is typically less expensive, and has greater resistance to stains.

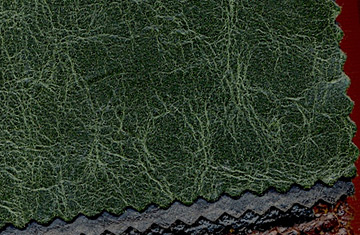

Corrected-grain leather is any leather that has had an artificial grain applied to its surface. The hides used to create corrected leather are of inferior quality that do not meet the high standards for use in creating vegetable-tanned or aniline leather. The imperfections are corrected and an artificial grain applied. Most corrected-grain leather is used to make pigmented leather as the solid pigment helps hide the corrections or imperfections. Corrected grain leathers can mainly be bought as two finish types: semi-aniline and pigmented.

Split leather is leather created from the fibrous part of the hide left once the top-grain of the rawhide has been separated from the hide. During the splitting operation, the grain and drop split are separated. The drop split can be further split (thickness allowing) into a middle split and a flesh split. In very thick hides, the middle split can be separated into multiple layers until the thickness prevents further splitting. Split leather then has an artificial layer applied to the surface of the split and is embossed with a leather grain (Bycast leather). Splits are also used to create suede. The strongest suedes are usually made from grain splits (that have the grain completely removed) or from the flesh split that has been shaved to the correct thickness. Suede is "fuzzy" on both sides. Manufacturers use a variety of techniques to make suede from full-grain. For example, in one operation, leather finish is applied to one side of the suede, which is then pressed through rollers; these flatten and even out one side of the material, giving it the smooth appearance of full-grain. Latigo is one of the trade names for this product. A reversed suede is a grained leather that has been designed into the leather article with the grain facing away from the visible surface. It is not a true form of suede.

Applications

FURNISHING

Because soft, even-grained leathers can be obtained that are resistant to light and/or to the fogging test in case of car furnishings.

CLOTHING

Because soft, lightweight leather can easily be obtained.

FOOTWEAR

Because thermal and physical resistances are comparable to, or even exceed, those obtained with chrome leathers.

LEATHER GOODS

Because with special adjustments during re-tanning reactive leather similar to vegetable leather can be obtained.

SMALL LEATHER GOODS

Because it is an advanced though low-cost process.

MECHANICAL LEATHERS

For the high physical resistances it imparts to finished leathers.

AUTOMOTIVE

Because an exceptional light weight leather with phisical properties can be achieved.